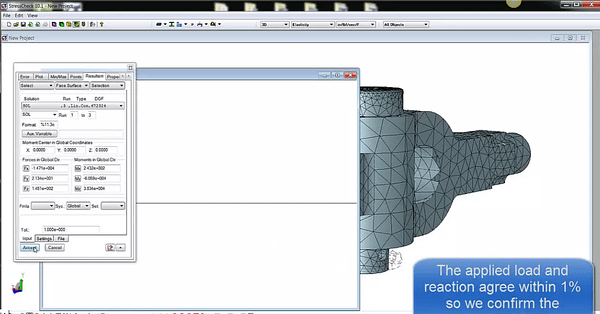

StressCheck Tutorial: Mapping Cold Working Residual Stresses to a Reamed Part via BRS Method

Abstract: Mapping residual stresses generated by cold working to a reamed part via Bulk Residual Stress (BRS) mapping and loading methods. Using Solution Configurations + Parts and the StressCheck BRS Module to:

- Solve a Cold Working (CX) analysis via Incremental theory of plasticity and Nonlinear Events

- Map the post-CX residual stress distribution to the reamed part using BRS mapping

- Apply the BRS-mapped stress distribution to the reamed part as a new load case

- Solve for stress redistribution in the reamed part.

For more details on the above methods: Helpful Hints and Tips: Cold Working and Reaming

Categories: Linear Elasticity Solver, Non-Linear Solver, Residual Stress Modules, StressCheck Core, StressCheck Professional. Tags: Boundary Conditions, BRS, Coldworking Stress, Detailed Stress, Material Properties, Nonlinear Analysis, Nonlinear Stress, Parametric Modeling, Parts, Plot Extraction, Residual Stress, Results, StressCheck GUI.

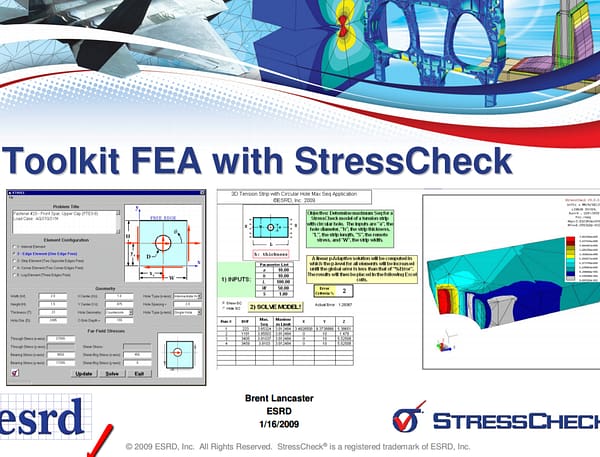

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989