StressCheck Tutorial: New Assembly Meshing/Auto Contact Features in StressCheck v12.0

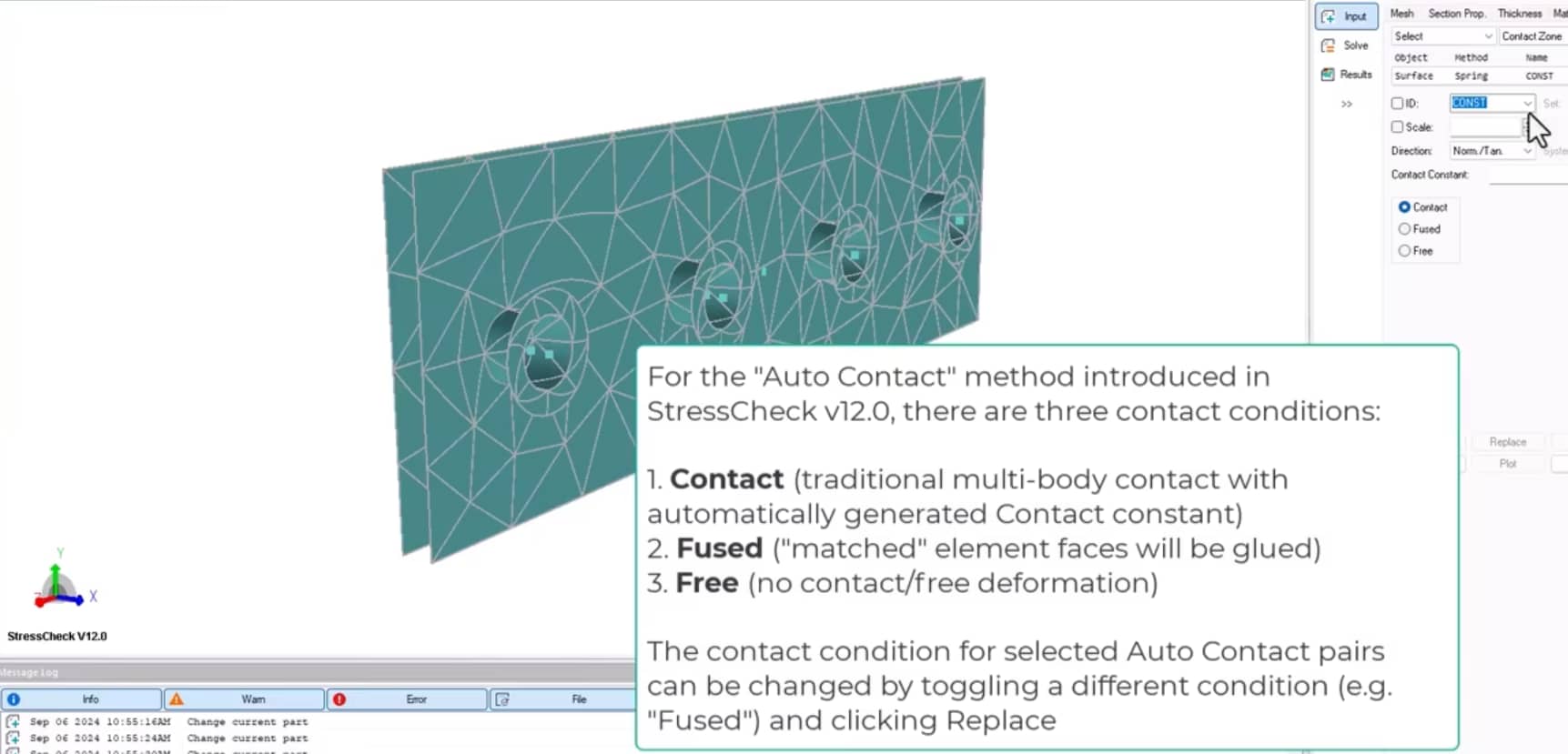

A new and powerful assembly automeshing/automatic contact detection feature is now available with the release of StressCheck v12.0. Before automeshing an assembly of close-contacting solid bodies, users may enable the “Assembly Meshing” option to enforce element face matching between neighboring surfaces (to within a user-specified tolerance). Once the solid bodies have been automeshed, StressCheck will automatically create contact zones between matched neighboring element faces and assign contact pairs via the new Auto Contact constraint method to the current constraint ID (if existing, otherwise StressCheck will use “AUTO_CONT” as the constraint ID).

Individual contact pairs generated via the Auto Contact method may specified as Contact (the default, traditional multi-body contact), Fused (if element face matching was 100% successful, matched element faces are bonded) or Free (matched element faces are free). Note that if individual contact pairs are specified as Contact, and a parameter is not used for the Contact Constant, the Contact Constant value is computed from the assigned material property data and will be updated if one or more of the material properties are modified.

This tutorial revisits a previous 3D multi-body contact example and utilizes assembly automeshing/automatic contact detection to significantly reduce the amount of setup time for multi-body contact analysis. The tutorial also demonstrates how refining the automesh (or updating a parameter value which triggers a re-mesh) will result in the re-generation of the contact zones/contact pairs.

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989