The Effects of Residual Tensile Stresses Induced by Cold-Working a Fastener Hole

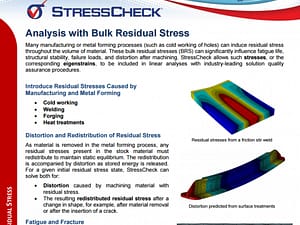

During a spectrum component fatigue test performed at IAI, a crack initiated at a notched edge near a cold-worked fastener hole, and propagated towards the hole. Fractographic analysis confirmed that the crack initiated at the edge and grew towards the hole. Since the maximum measured stress in the notch was not sufficiently high to explain crack-initiation during the test, it was suspected that the tensile residual stresses at the edge contributed to the cracking. An experimental study was initiated in order to measure the tensile residual stresses induced by cold working at various edges located near cold-worked holes. Tensile residual stresses as high as 35 ksi were measured at an edge near a cold-worked hole. Elastic-Plastic finite-element analysis results (ABAQUS and StressCheck) showed good agreement with the experimental results. Fatigue analysis has shown that when these residual stresses are combined with high cyclic notch stresses that arise from external loading, the fatigue life at the edge can be drastically reduced.

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989