Hit the play button to view this video. You may maximize the video to fit your screen.

StressCheck Demo: Benchmarking 3D Stress Concentration Factors via Numerical Simulation

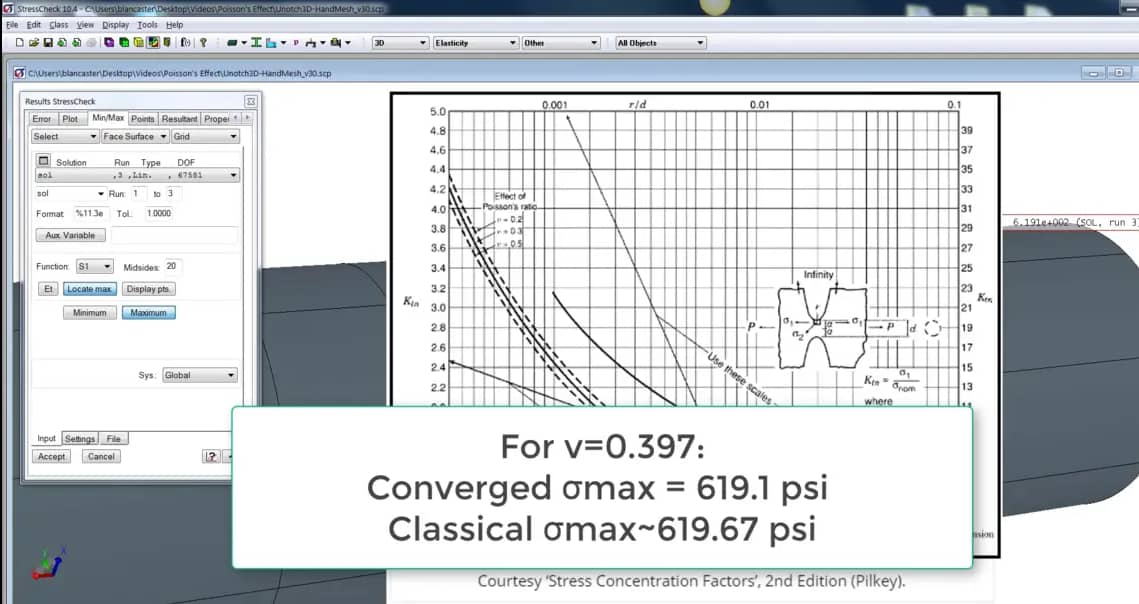

Abstract: A benchmarking-by-FEA case study is performed for a tension bar of circular cross section with a semi-circular groove. The goal was to compute the 3D stress concentration factor by classical approximation (Walter D. Pilkey’s ‘Peterson’s Stress Concentration Factors’, Section 2.5.2) and Numerical Simulation (StressCheck FEA) for several Poisson’s ratio values, and demonstrate the effect of Poisson’s ratio on the 3D stress concentration factors.

For each StressCheck FEA simulation, solution verification was performed to show the maximum stress converged and was independent of degrees of freedom.

Read the a full discussion on this benchmark case study, and how Key Quality Checks must be passed before performing any benchmarking-by-FEA.

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989