By Dr. Barna Szabó

Engineering Software Research and Development, Inc.

St. Louis, Missouri USA

It is generally recognized that explainable artificial intelligence (XAI) will play an important role in numerical simulation where it will impose the requirements of reliability, traceability, and auditability. These requirements will necessitate clear thinking about the nature of mathematical models, the trustworthiness of their predictions, and ways to improve their reliability.

What is a Mathematical Model?

A mathematical model is an operator that transforms one set of data D, the input, into another set, the quantities of interest F. In shorthand notation we have:

\boldsymbol D\xrightarrow[(I,\boldsymbol p)]{}\boldsymbol F,\quad (\boldsymbol D, \boldsymbol p) \in ℂ \quad (1)where the right arrow represents the mathematical model. The letters I and p under the right arrow indicate that the transformation involves an idealization (I) as well as parameters (physical properties) p that are determined by calibration. Restrictions on D and p define the domain of calibration ℂ, which is also called the domain of application of the mathematical model.

The formulation of mathematical models is a creative, open-ended activity, guided by insight, experience, and personal preferences. The validation and ranking of mathematical models, on the other hand, are based on objective criteria.

The systematic improvement of the predictive performance of mathematical models and their validation is, essentially, a scientific research program. According to Lakatos [1], a scientific research program has three constituent elements: (a) a set of hardcore assumptions, (b) a set of auxiliary hypotheses, and (c) a problem-solving machinery.

In the applied sciences, the hardcore assumptions are the assumptions incorporated in validated models of broad applicability, such as the theory of elasticity, the Navier-Stokes equations, and the Maxwell equations. The objects of investigation are the auxiliary hypotheses.

For example, in linear elastic fracture mechanics (LEFM), the goal is to predict the probability distribution of the length of a crack in a structural component, given the initial crack configuration and a load spectrum. In this case, the hardcore assumptions are the assumptions incorporated in the theory of elasticity. One auxiliary hypothesis establishes a relationship between a functional defined on the elastic stress field, such as the stress intensity factor, and increments in crack length caused by the application of cyclic loads. The second auxiliary hypothesis accounts for the effects of overload and underload events. The third auxiliary hypothesis models the statistical dispersion of crack length.

The parameters characterize the relationships defined by the auxiliary hypotheses and define the material properties of the hardcore problem. The domain of calibration ℂ is the set of restrictions on the parameters imposed by the assumptions in the hardcore hypothesis and limitations in the available calibration data.

Problem-Solving

The problem-solving machinery is a numerical method, typically the finite element method. It generates an approximate solution from which the quantities of interest Fnum are computed. It is necessary to show that the relative error in Fnum does not exceed an allowable value τall:

| \boldsymbol F - \boldsymbol F_{num} |/|\boldsymbol F| \le \tau_{all} \quad (2)To achieve this goal, it is necessary to obtain a sequence of numerical solutions with increasing degrees of freedom [2].

Demarcation

Not all model development projects (MDPs) are created equal. It is useful to differentiate between progressive, stagnant, and improper MDPs: An MDP is progressive if the domain of calibration is increasing; stagnant if the domain of calibration is not increasing, and improper if the auxiliary hypotheses do not conform with the hardcore assumptions, or the problem-solving method does not have the capability to estimate and control the numerical approximation errors in the quantities of interest. Linear elastic fracture mechanics is an example of stagnant model development projects [3].

Presently, the large majority of engineering model development projects is improper. The primary reason for this is that finite element modeling rather than numerical simulation is used, hence the capability to estimate and control the numerical approximation errors is absent.

Finite element modeling is formally similar to equation (1):

\boldsymbol D\xrightarrow[(i,\boldsymbol p)]{} \overline {\boldsymbol F}_{num} \quad (3)where lowercase i is used to indicate intuition in the place of idealization (I) and F̅num replaces F. The overbar is used to distinguish the solutions obtained by finite element modeling and proper application of the finite element method.

In finite element modeling, elements are intuitively selected from the library of a finite element software tool and assembled to represent the object of analysis. Constraints and loads are imposed to produce a numerical problem. The right arrow in equation (3) represents a ”numerical model”, which may not be an approximation to a well-defined mathematical model, in which case F is not defined and F̅num does not converge to limit value as the number of degrees of freedom is increased. Consequently, error estimation is not possible. Also, the domain of calibration has a different meaning in finite element modeling than in numerical simulation.

Opportunities for Improving the Predictive Performance of Models

There is a very substantial unrealized potential in numerical simulation technology. To realize that potential, it will be necessary to replace the practice of finite element modeling with numerical simulation and utilize XAI tools to aid analysts in performing simulation projects:

- Rapid advancements are anticipated in the standardization of engineering workflows, initially through the use of expert-designed engineering simulation applications equipped with autonomous error control procedures.

- XAI will make it possible to control the errors of approximation very effectively. Ideally, the information in the input will be used to design the initial mesh and assignment of polynomial degrees in such a way that in one or two adaptive steps the desired accuracies are reached.

- XAI will be less helpful in controlling model form errors. This is because the formulation of models involves creative input for which no algorithm exists. Nevertheless, XAI will be useful in tracking the evolutionary changes in model development and the relevant experimental data.

- XAI will help navigate numerical simulation projects.

- Prevent the use of intuitively plausible but conceptually wrong input data.

- Shorten training time for the operators of simulation software tools.

The Main Points

- The reliability and effectiveness of numerical simulation can be greatly enhanced through integration with XAI processes.

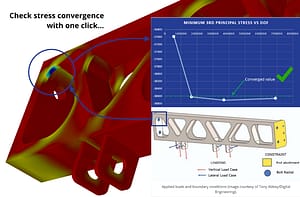

- The main elements of XAI-integrated numerical simulation processes are shown in Figure 1:

- The integration of numerical simulation with explainable artificial intelligence tools will force the adoption of science-based algorithms for solution verification and hierarchic modeling approaches.

References

[1] I. Lakatos, The methodology of scientific research programmes, vol. 1, J. Currie and G. Worrall, eds., Cambridge University Press, 1972.[2] B. Szabó and I. Babuška, Finite Element Analysis. Method, Verification and Validation. 2nd edition, John Wiley & Sons, Inc., 2021. [3] Szabó, B. and Actis, R. The demarcation problem in the applied sciences. Computers and Mathematics with Applications, Vol. 162, pp. 206–214, 2024.Related Blogs:

- Where Do You Get the Courage to Sign the Blueprint?

- A Memo from the 5th Century BC

- Obstacles to Progress

- Why Finite Element Modeling is Not Numerical Simulation?

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989

Leave a Reply

We appreciate your feedback!

You must be logged in to post a comment.