The Composites Affordability Initiative (CAI) unanimously selected ESRD’s composites functionality to “replace as well as radically improve existing industry software currently used for bonded joints.” In time, the improvements extended to fastened laminated composite and metallic-laminated joints, reinforced composite structures, multi-scale analysis and more.

Composites Applications

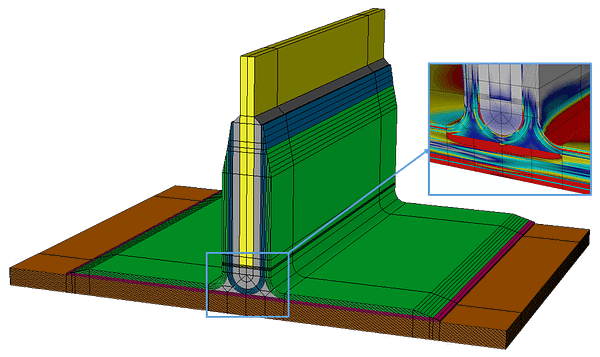

Our implementation is unique in the FEA industry for focusing on the detailed analysis needs of composite designers and engineers, including 3D ply-by-ply modeling and failure analysis.

Schedule a Composites Demo

Would you like a no-cost demonstration of our composites engineering application solutions? Complete our Request an Engineering Application Demo form and we will get back to you shortly.

Composites Application Focus

The following are typical composites analysis applications which are routinely performed in StressCheck Professional:

Linear Elasticity Solver

Composites Module

Non-Linear Solver

Margin Check Solver

Linear Elasticity Solver

Composites Module

Non-Linear Solver

Margin Check Solver

Heat Transfer Solver

Linear Elasticity Solver

Composites Module

Heat Transfer Solver

Would you like to schedule a Composites Analysis Demo?

Would you like to learn more about our features and solutions for laminated composites analysis applications? Schedule a Composites Analysis demo with us by completing the below form and we’ll contact you as soon as possible. Thank you!

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

The software provides a highly reliable and user-friendly production stress analysis tool that will replace the Finite Element Method (FEM) tools and failure criteria the experts currently employ for analyzing bonded joints. The software includes an FEM-based handbook format, which allows non-experts to utilize models prepared by specialists. The handbook problems include built-in failure criteria, geometric and material nonlinearities, and the modern FEM technology provides better error control and the treatment of very large aspect ratios.”

Dr. Stephen P. Engelstad

Technical Fellow, Lockheed Martin Aeronautics Company, Structural Methods and Analysis

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989