ESRD, Inc. will be exhibiting, presenting a technical paper (on DTA of bonded repairs) and providing a 2-hour training course in person and virtually at the ASIP Conference 2023 in Denver, CO from November 27-November 30, 2023. We hope you will drop by our technical presentation, training course and/or booth to check out the latest ESRD developments!

ESRD’s Training Course

A 2-hour training course titled “Enhancements in StressCheck v12.0 for DaDT Analysis of 3D Fastened Joints” will be held Monday, November 27th from 10:00 AM – 12:00 PM MST by ESRD’s Brent Lancaster. The course description is as follows:

As more DaDT and service life analysis (SLA) engineers look to incorporate the influence of assembly multi-body contact, fastener hole propping and/or fastener load transfer into their beta factor and/or stress intensity factor (SIF) predictions, it is imperative that the numerical simulation of these effects on 3D fracture mechanics parameters can be ascertained without inflicting cumbersome modeling workflows, endless meshing cycles, and high computational costs on the end user. This training course will outline proposed methodologies, guidelines and best practices for ESRD’s StressCheck Professional finite element analysis (FEA) software to perform efficient and accurate DaDT analysis of flawed 3D fastened connections and multi-body contact assemblies, including enhanced automeshing and SIF extraction techniques now available in StressCheck v12.0. In addition, several live demonstrations of technology will be performed for representative use cases.

In this 2-hour training course, we will focus on the following topics:

- StressCheck’s FEA technology implementation for the modeling, meshing and analysis of arbitrarily shaped 3D crack geometries, with and without the local effects of multi-body contact.

- Strategies for automatic meshing of 3D cracks with high-aspect ratio, 3D-solid pentahedral and hexahedral elements to support high-quality SIF extractions at any location on the crack front.

- New StressCheck v12.0 method to support multi-body contact assembly meshing, auto-detection of contact regions, and automatic assignment of contact pairs for 3D solid bodies.

The training course content will be based on concepts from the following resources, available on ESRD’s Resource Library and online documentation:

- ASIP 2018 Training – Modeling Fastened Connections: Hierarchic Approaches Discussion and Demo

- Helpful Hints and Tips: 3D Stiffened Lug Stress + Crack SIF Analyses

- Helpful Hints and Tips: Interference Fit Bushing + SIFs

- StressCheck Demo: Part-Thru Crack SIFs for Stiffened Lug

- StressCheck Tutorial: 3D Elliptical Part-Thru Crack with Multi-Body Contact

- StressCheck Tutorial: Filled vs Open Hole SIF Comparison for 3D Offset Hole

ESRD’s Technical Presentation

A 30-minute technical presentation titled “Experimental Validation of DTA Modeling of Bonded Wing Skin Repairs” and authored by Mr. Brian Lockwood (ESRD), Ms. Laura Pawlikowski (Warner Robins ALC) and Dr. Scott Prost-Domasky (AP/ES) will be presented by Brian Lockwood on Thursday, November 30th at 10:30 AM MST.

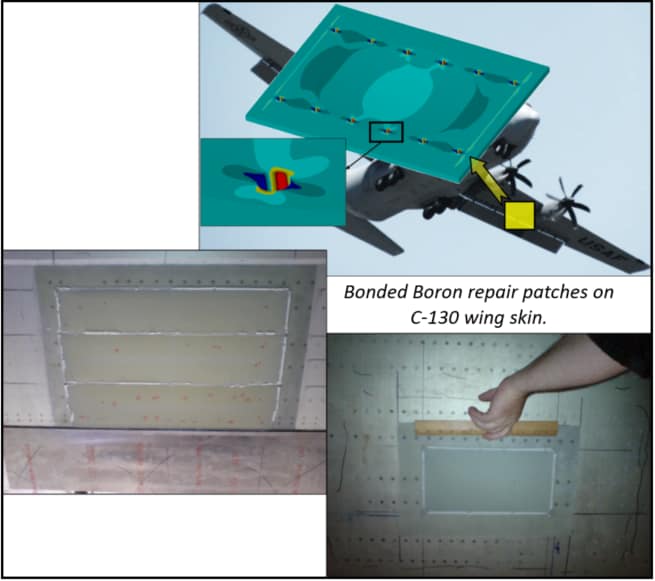

As the principal investigator on this USAF SBIR-funded project, Brian will be presenting an update to his work so far in utilizing StressCheck’s finite element analysis implementation to assess the effectiveness of bonded skin repairs on the C-130 center wing. The technical presentation description is as follows:

This presentation is a follow-up to ESRD’s 2022 ASIP presentation titled “DTA of Bonded Repairs on the Wing Skin of the C-130 Using Finite Elements.” That presentation explored a robust method for finite element analysis of bonded skin repairs from the perspective of both static strength and fatigue crack growth. The proposed analysis methodology was presented in a comparative sense, examining a number of criteria in the skin in an undamaged state, a damaged state and a repaired state, in order to allow the analyst to make an assessment of repair effectiveness without detailed knowledge of either the exact boundary conditions of the problem, or of the intricacies of the model itself. One of the criteria for a patch to be deemed effective is that the fatigue life of the skin be at or above that of the pristine configuration.

Given the sparse nature of research on the topic of crack growth under bonded repair patches, ESRD partnered with AP/ES to conduct an experimental program to investigate in detail how a small initial flaw propagates in the aluminum skin under a titanium repair up through failure. Experiments were performed alongside blind predictions of life and crack morphology using ESRD’s research tool, CPAT. Additionally, statistical analysis was performed to assess confidence in the predictions. Given the aleatory uncertainty associated with the available crack growth data for the specimen material, it was important that predictions of fatigue life be accompanied by a confidence level when comparing them with experimental outcomes. Because most of the crack propagation occurred under the repair, a marker band spectrum was used during the test and the crack-cycle data was constructed from fractographic examination. The experimental program covered three specimen configurations:

- Undamaged skin with a surface crack or a corner crack at a hole.

- Skin with a grindout (to remove hypothetical corrosion damage) and either a surface crack at the bottom of the grindout or a corner crack at a hole located at the center of the grindout.

- Same as previous configuration, but including a bonded titanium repair.

Experimental and predicted results will be presented.

ESRD’s Exhibit Booth

ESRD can be found at Booth 5 and will have several staff members available to chat, provide demonstrations, troubleshoot issues (StressCheck Clinic), and answer questions about our training course, our technical presentation, our software products and our composite repair solutions.

We’ll be handing out some fun giveaways at our booth! Stop by early to chat with us and grab one!

Participating ESRD Staff

Contact information for ESRD staff participating in ASIP Conference 2023 is as follows:

- Mr. Brent Lancaster – brent.lancaster@esrd.com

- Mr. Brian Lockwood – brian.lockwood@esrd.com

- Mr. Patrick Goulding – patrick.goulding@esrd.com

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989

Leave a Reply

We appreciate your feedback!

You must be logged in to post a comment.