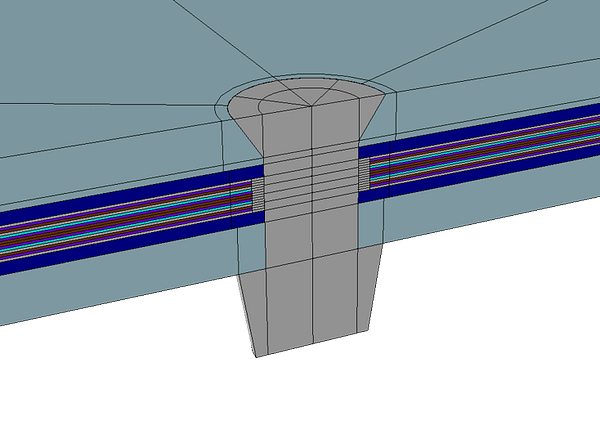

3D ply-by-ply analysis with the Composites Module, enhanced through our Automatic Laminate Builder, allows you to conveniently estimate the interlaminar stresses and strains required to accurately predict interlaminar failure or assess the structural integrity of the joint.

Composites Module

StressCheck also allows you to extract results for a laminate as well as an individual ply within a laminate. Stress or strain results are available in the material direction of each ply, in addition to the global or other coordinate system directions. Failure criteria can be user-defined by one or more formulaic expressions, or using the Failure Criteria interface, and cleanly assessed during post-processing.

Key Features and Advantages

- The advanced FEA formulation in StressCheck allows high aspect ratio elements, for example 200:1 or larger, enabling ply-by-ply element modeling while reducing model size.

- The powerful Automatic Laminate Builder functionality automatically subdivides a given “parent” mesh into a ply-by-ply representation, saving significant time and effort.

- Fiber orientations for each ply can precisely follow the curvature of the underlying geometry, providing a highly accurate representation of material directions.

- Visualization of fiber orientations and their associated principal directions available as a display attribute.

- Attributes of composite models can be fully parametric, including plies produced from the Automatic Laminate Builder process.

- Thin solid elements in StressCheck allow substantial savings in computational time, without compromising the quality and accuracy of the solution.

- This is exceptionally valuable when analyzing composites where ply-by-ply element modeling is used.

- Composites be combined with the Margin Check and Non-Linear Solver modules for additional analysis.

- The Margin Check Solver is useful for limit load analysis in which multiple failure criteria are assessed at multiple locations.

- The Non-Linear Solver is useful for assessing adhesive failure for laminated composite bonded structures.

- Fully supports multi-body contact for capturing fastener propping, clamping and other load transfer effects.

- Failure analysis of adhesively bonded composite joints, composite damage assessment, limit load analysis, and other user-defined extraction options available with Composite post-processing.

- Formulaic expressions may be defined for failure criteria, such as Tsai-Hill for example, and applied during Composites post-processing.

- Separated Energy Release Rates, available in the Fracture Mechanics module, allow for delamination studies.

- Primary quantities used to assess failure of composites, such as the first strain invariant J1 and volumetric strain can be calculated through the Failure Criteria interface.

- Ply by ply stresses, strains and user-defined engineering formulae are available for extraction, anywhere within the laminate/lamina/bondline for any solution (Linear, Non-Linear, etc.).

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“At DST Group, we have effectively used StressCheck over the last 10 years to determine accurate stress intensity factors. The results have been used to improve our residual strength and structural life estimates for aircraft in service with the Royal Australian Airforce, including C-130, P-3C and F/A-18 A/B. We have found it to be extremely easy to use and a very versatile code with which to create parametric models.

We have recently used StressCheck to obtain improved stress intensity factor solutions (Improved stress intensity factors for selected configurations in cracked plates and Improved stress intensity factors for a single corner crack at a loaded fastener hole) for five key generic configurations. These transferable parametric results have been published externally. One specific example is the non-linear contact analysis of a cracked, filled fastener hole, with both fastener and remote plate loading.”

Dr. Manfred Heller, Head

Structural & Damage Mechanics, DST Group

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989