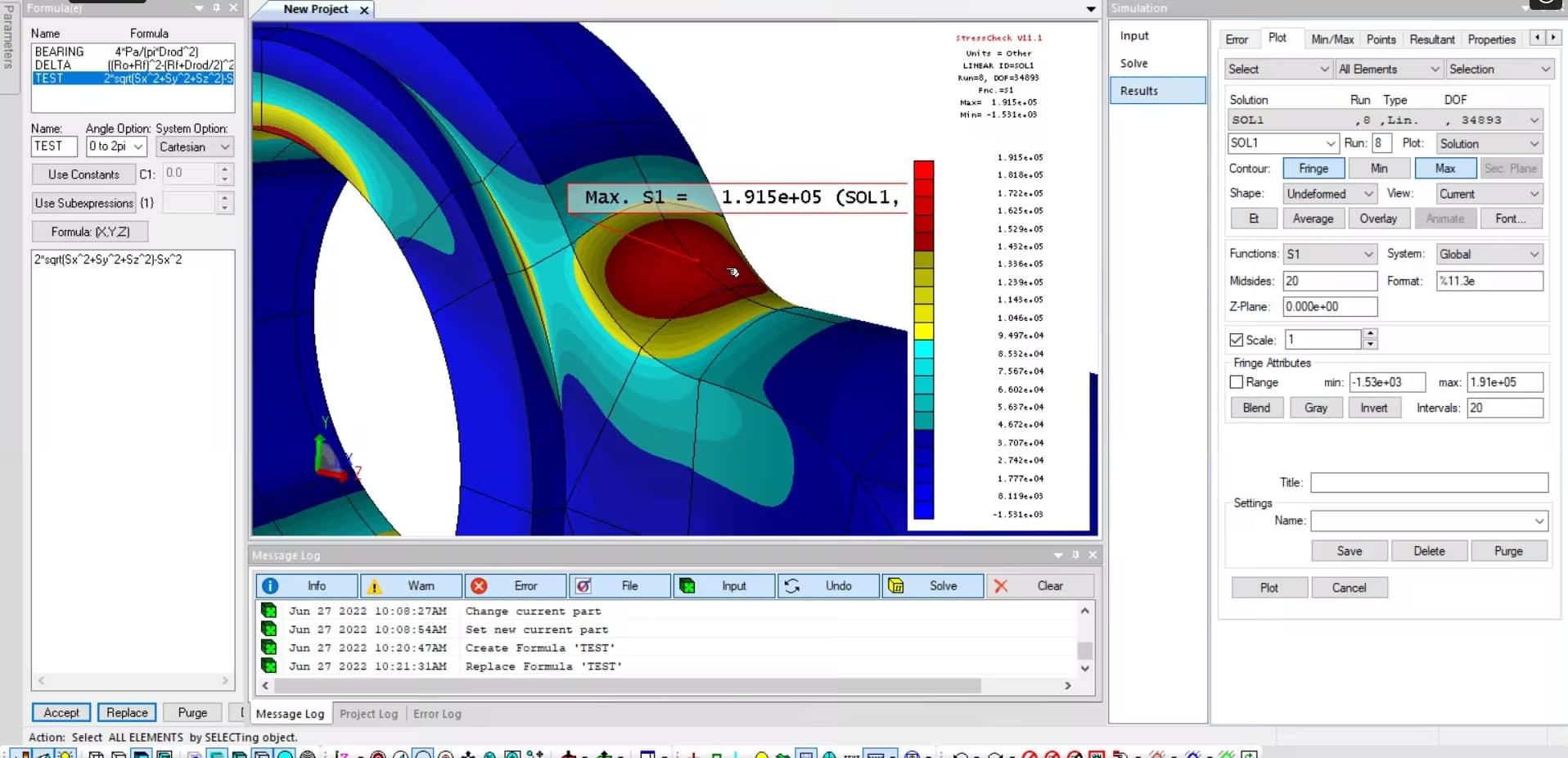

StressCheck’s Linear Elasticity Solver allows you to confidently investigate solid mechanics-based modeling concepts before manufacturing expensive prototypes, modifying existing structural details and/or developing novel repair concepts. Why confidently? Because our solver implementation inherently separates modeling errors from numerical approximation errors, helping you simplify the engineering decision-making process.

Linear Elasticity Solver

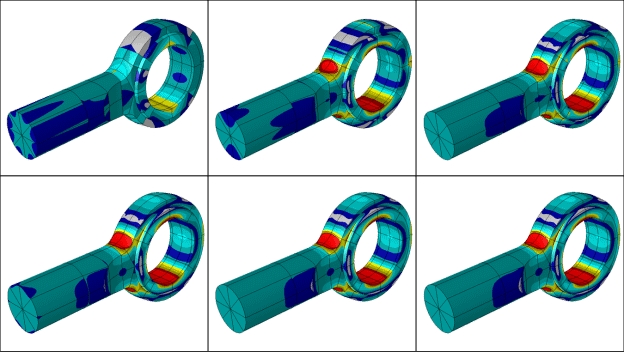

The Linear Elasticity Solver is the initial building block of the seamless hierarchic modeling framework that constitutes the foundation of StressCheck. Sequential linear elastic solutions are obtained automatically by increasing the polynomial level of the elements, and subsequent advanced analyses use linear solutions as a basis.

Key Features and Advantages

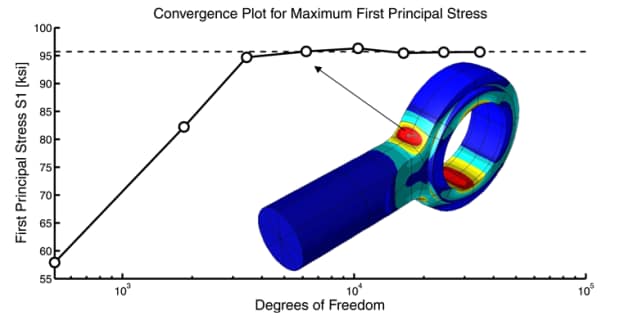

- Solutions can be obtained by p-extension and adaptive-p methods with convergence-based criteria

- Allows for easy verification of results without mesh refinement

- It is simple and easy to extend a linear elastic solution to higher p-levels

- Multiple solutions can be obtained for the same mesh and convergence in the data of interest can be checked by increasing the number of degrees of freedom (DOF) by p-extension.

- Includes support for multi-body contact analysis, with no inherent limit on assembly size

- Solutions on the order of 50 million DOF or more can be computed

- Provides product development professionals with the most widely used and needed analysis capabilities for structural analysis

- Identify problem areas and test ideas virtually before building expensive prototypes and experimental fixtures

- Powerful and extensible – this is the prerequisite module to run advanced analysis types (e.g. nonlinear, margin check, cold-working, modal/buckling)

- Supports planar (plane stress, plane strain), extruded, axisymmetric, and 3D elasticity analysis

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

When performing parametric structural analysis, ESRD’s p-element StressCheck FEA software is always my preferred choice due to the excellent solution quality, parametric framework, and superior computational efficiency. In fact, I recently used StressCheck to generate stress intensity factors along a parametrically defined elliptical crack-tip across 3,000 unique geometric configurations. Considering multi-body contact was present and all simulations were performed using a laptop, this was a task well suited for StressCheck.

Dr. Lee Zambino

Researcher, Villanova University

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989