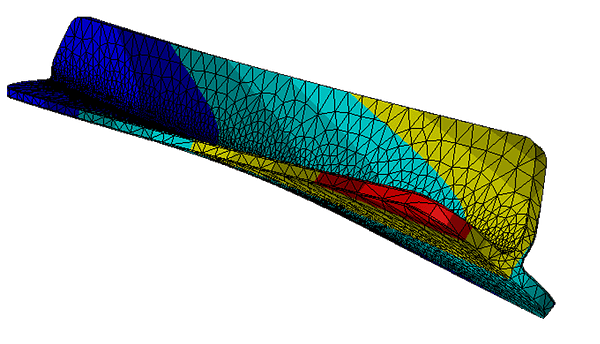

Are machining-induced residual stresses causing unacceptable distortion? Need to simulate the influence of cold working sequence for a given hole pattern? Residual stresses (RS) can have a significant impact on the strength, durability and damage tolerance of metallic and composite parts. In the past, reliably simulating RS effects was challenging due to extreme stress gradients, especially in lightweight components.

Residual Stress Applications

RS effects can be beneficial, such as life extension by cold working one or more fastener holes, or detrimental, such as distortion leading to expensive re-working or rejection of large, lightweight manufactured parts. Are you in good shape?

Schedule a Residual Stress Demo

Would you like a no-cost demonstration of our residual stress and distortion prediction engineering application solutions? Complete our Request an Engineering Application Demo form and we will get back to you shortly.

Residual Stress Application Focus

The following are typical residual stress analysis applications which are routinely performed in StressCheck Professional:

Linear Elasticity Solver

Non-Linear Solver

Cold Working Solver

Linear Elasticity Solver

Bulk Residual Stress (BRS) Module

Subsurface Residual Stress (SRS) Module

Linear Elasticity Solver

Fracture Mechanics Module

MeshSim Advanced Automesher

Bulk Residual Stress (BRS) Module

Subsurface Residual Stress (SRS) Module

Would you like to schedule a Residual Stress Analysis Demo?

Would you like to learn more about our features and solutions for cold working and residual stress analysis applications? Schedule a Residual Stress Analysis demo with us by completing the below form and we’ll contact you as soon as possible. Thank you!

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“An advanced modeling and analysis tool for complex composite structures is generating benefits across the aerospace industrial base. StressCheck [Composites] is widely viewed as the next-generation composite joint strength tool.”

Air Force Research Laboratory (AFRL)

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989