The Multi-Fastener Analysis Tool (MFAT) is a Smart Engineering Simulation App providing effortless modeling of single or double shear joints, including lap joints, splice joints and doublers (with or without a repair cutout), within a Planar setting. MFAT supports metallic and composite plates, and allows for any number of fasteners with neat fit, interference fit or clearance fit.

Multi-Fastener Analysis Tool

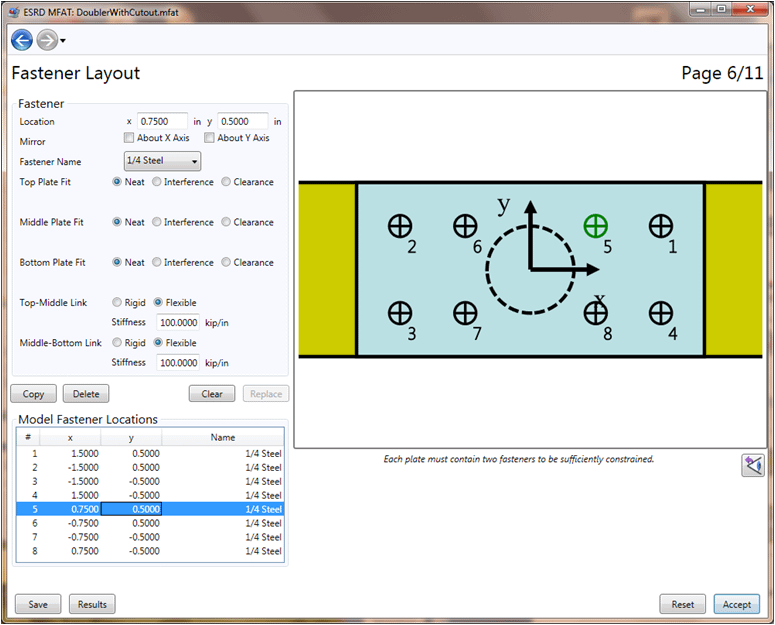

MFAT accounts for both the radial stiffness of the fastener and the fastener fit, including the nonlinear interaction between the fastener shank and the fastener hole. MFAT also includes the effect of the shear/bending stiffness of each fastener, the value of which can be accurately computed with SFAT. The FE mesh is built ‘on the fly’ based on input provided by the user in a very intuitive interface. Fastener load transfer results obtained with MFAT are presented in tabular form and depicted graphically, and they compare well with experimental data published in the literature.

Key Features and Advantages

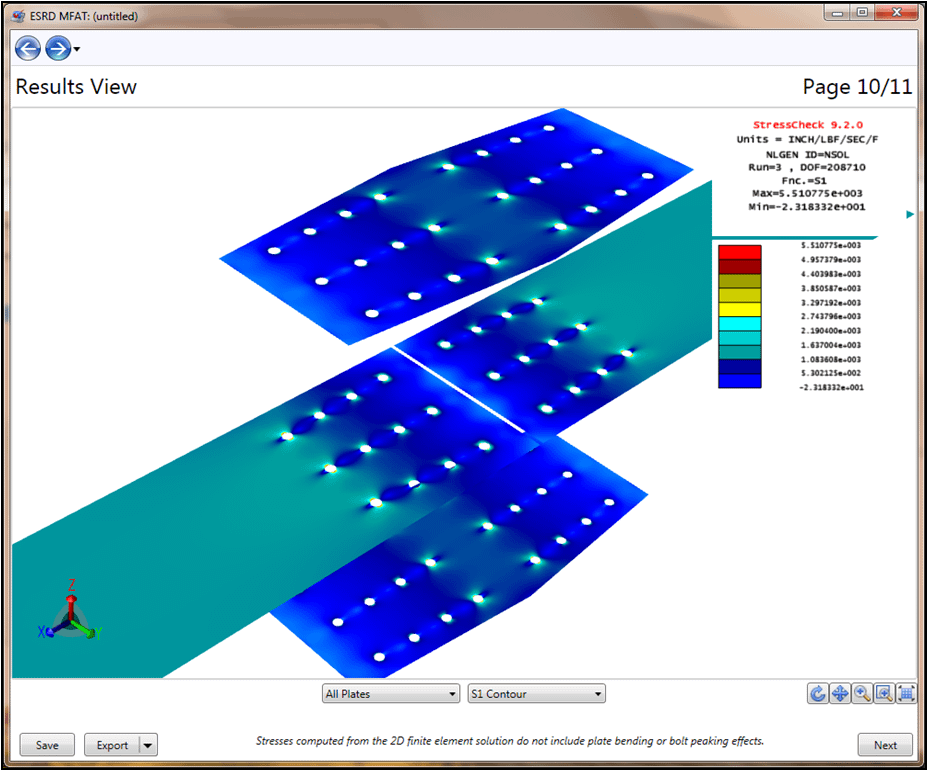

- Solutions are obtained with StressCheck, with quality verified by p-extension.

- Modeling approach validated with experimental results.

- Built-in results viewer provides dynamic viewing of FE mesh and stress fringe contours.

- Supports US and SI units.

- Simulate influence of fastener fit in load transfer.

- Solution time is reduced from hours to minutes when compared with standard FEA.

- Simplified user interface provides input of fastener data in pre-defined templates with step by step validation feedback.

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“We have found StressCheck very useful for computational fracture mechanics for both metallic and composite components. In recent years it has been extensively used in determining beta factors for RAAF’s C-130 Wing DTA locations and associated generic research.”

Dr. Manfred Heller

Head - Structural Mechanics, DSTO

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989