Strategies for seamlessly integrating the advanced fracture & DaDT capabilities of two numerical simulation software products into a state-of-the-art 3D fatigue crack growth application will be explored.

July 17, 2019 @ 1:00 pm EST

3D Crack Growth Simulation: Advancements & Applications

This webinar is now available to watch on-demand.

WEBINAR SUMMARY

In this webinar we will detail the latest technological advancements for accurate simulation of three-dimensional metallic crack growth via coupled finite element analysis (FEA) and fatigue life computations. Additionally, we will examine why the development of more complex crack growth models requires both tighter control over numerical errors (i.e. solution verification) and rigorous benchmarking to standard handbook solutions and available experimental data (i.e. model validation).

WEBINAR HIGHLIGHTS

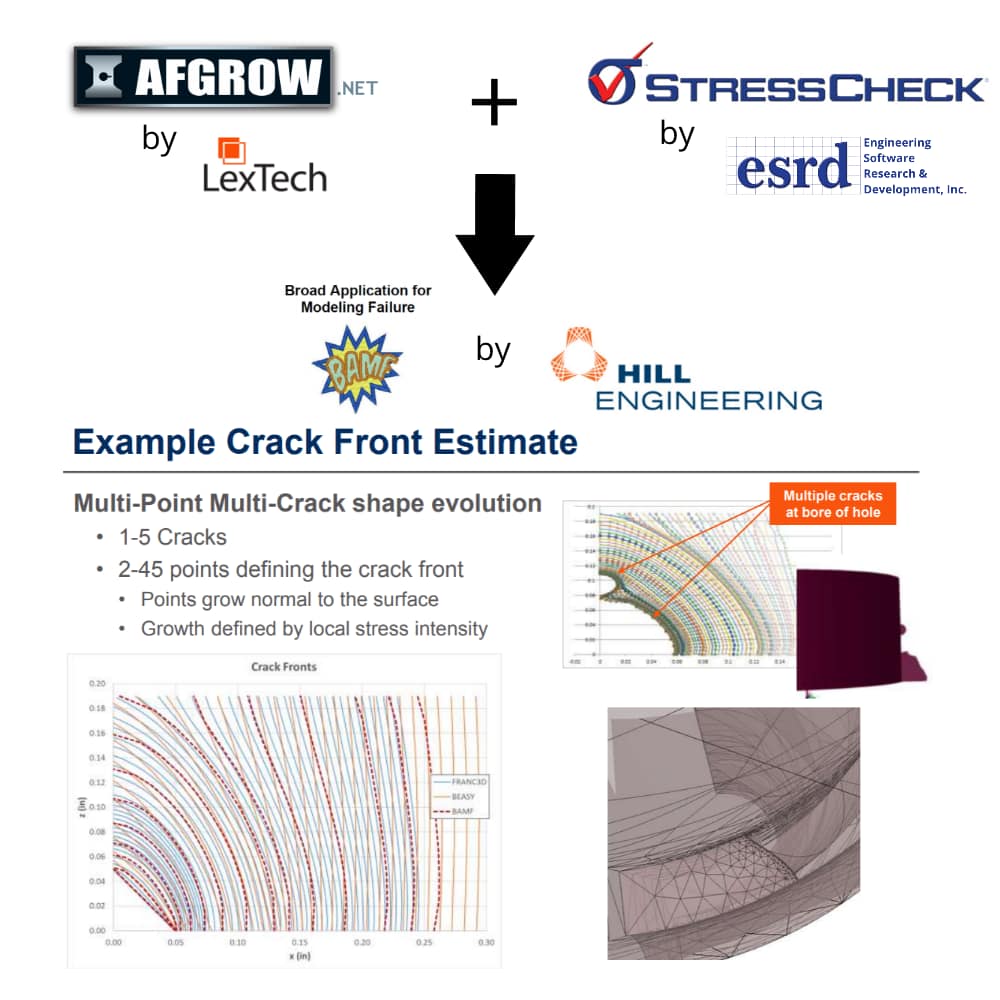

- This webinar will be jointly presented by ESRD, Hill Engineering, LLC (developers of BAMF) and LexTech, Inc. (developers of AFGROW), and will explore the latest technologies, methodologies and software implementations available for DaDT and fatigue engineers to numerically simulate fatigue crack propagation.

- The effects of engineered residual stresses (ERS) on crack shape evolution and the associated cyclic fatigue life will be assessed in several practical case studies.

- LIVE DEMO: You will see a 3D crack growth demonstration with Hill Engineering’s Broad Application for Modeling Failure (BAMF) software tool, which provides a robust integration between StressCheck’s DaDT/fracture solutions and AFGROW’s crack growth life prediction capabilities.

WEBINAR PARTICIPANTS

StressCheck is a comprehensive Windows 10-compatible, 64-bit finite element analysis software (FEA) tool with a fully integrated pre- and post-processor and a suite of solver and analysis modules that support advanced engineering computations in applications of solid mechanics. Productivity tools are available to import NASTRAN bulk data file meshes and CAD geometry, perform 2D and 3D automatic meshing, automate analyses via StressCheck‘s API, and more. StressCheck is ideally suited for damage tolerance and forensic engineers who need the best representation of 2D or 3D SIF’s, ERR’s and beta factors for input in sophisticated crack growth simulations, or when analyzing repairs for mitigation of cracks.

AFGROW is a Damage Tolerance Analysis (DTA) framework that allows users to analyze crack initiation, fatigue crack growth, and fracture to predict the life of metallic structures. AFGROW (Air Force Grow), was originally developed by The Air Force Research Laboratory. It is now being developed and maintained by LexTech, Inc. AFGROW is one of the most efficient and widely used crack growth life prediction tools available today. AFGROW is mainly used for aerospace applications; however, it can be applied to any type of metallic structure that experiences fatigue cracking. AFGROW is also a very flexible and user-friendly computer program.

BAMF is used for fatigue analysis, and it is capable of predicting the growth of fatigue cracks in 3D parts. Starting from an assumed initial flaw, BAMF combines stress and crack growth analyses to predict the evolution of crack shape and size in 3D. BAMF provides a robust and automated link between two leading tools: AFGROW and StressCheck. Key features of BAMF include: natural crack shape evolution, fully 3D fatigue analysis capability, complex loading support, multiple cracks, and residual stress compatibility.

WATCH THIS WEBINAR

Part 1: Introduction & Implementation Requirements

Part 2: StressCheck & AFGROW Features

Part 3: BAMF Demo & Webinar Summary

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“As the United States Air Force continues to extend the service life of their aircraft the Aircraft Structural Integrity Program (ASIP) has had to refine the methods it uses to analyze and predict fatigue crack growth. Through the use StressCheck, coupled with AFGROW, we in A-10 ASIP have been able to more accurately model, predict and analyze critical aircraft structure for the A-10 and other types of structure for non-A-10 system managers. This also allows us within the A-10 to more accurately assess risk for decision makers, streamline aircraft inductions into scheduled maintenance and reduce cost for total life cycle management.”

A-10 ASIP Manager

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989