Strategies will be explored for developing mathematical models to support condition-based maintenance (CBM) decisions via a practical case study.

April 22, 2021 @ 11:00 am EST

Simulation Governance Is Critical for Reliable Condition-Based (Predictive) Maintenance

WEBINAR SUMMARY

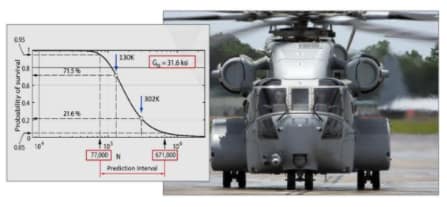

This webinar, hosted by ESRD partner Revolution in Simulation, will present a case study in which the goal was the development of a mathematical model for supporting condition-based maintenance (CBM) decisions.

The model was designed for estimating the remaining fatigue service life of high-value mechanical components, given their service history and that specific flaws (such as corrosion defects) have been discovered in them, thus enabling CBM to move damaged component removals from unscheduled to scheduled maintenance action.

WEBINAR HIGHLIGHTS

- Mathematical models have both intuitive, creative components and objective, science-based components. These two components must be in equilibrium.

- What is the difference between finite element modeling and numerical simulation?

- What is the domain of calibration and how to specify it?

- How the outcome of validation experiments should be evaluated and reported?

- Why is the development of mathematical models open-ended? – Why no one can claim to have the last word?

- Why simulation governance is essential for the success of numerical simulation projects?

REGISTER FOR THIS WEBINAR

Click the below button to be re-directed to Revolution in Simulation’s webinar registration page:

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“Hearty congratulations to management and staff at ESRD on their 25th anniversary. The quality and capability of their software products are excellent. I hope that ESRD successfully continues for many more years with the fundamental principles of mathematical precision, numerical accuracy, and integrity in computational simulation.”

Dr. William Oberkampf

Author of Verification and Validation in Scientific Computing

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989