What inhibits the use of FEA for DaDT applications in the A&D Industry?

In this “S.A.F.E.R. Simulation” post we will share the key takeaways for engineers and their managers from a recent ESRD...

In this “S.A.F.E.R. Simulation” post we will share the key takeaways for engineers and their managers from a recent ESRD...

ESRD, Inc. will be exhibiting and providing a training course on verifying the accuracy of engineering simulations at the AA&S/PS&S Conference 2019 in Washington, D.C. from April 22-26, 2019. We hope you will drop by our training course and booth to check out the latest!

July 17, 2019 @ 1:00 pm EST

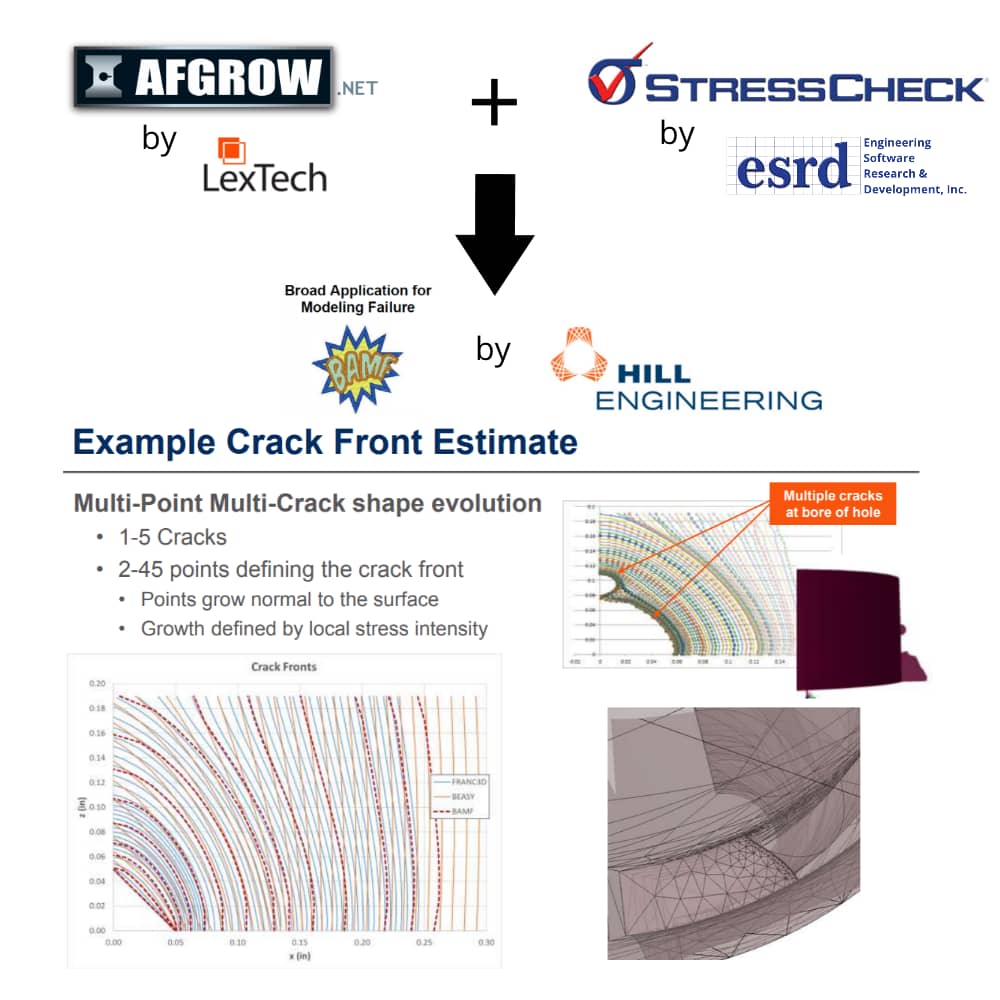

Strategies for seamlessly integrating the advanced fracture & DaDT capabilities of two numerical simulation software products into a state-of-the-art 3D fatigue crack growth application will be explored.

This webinar is now available to watch on-demand.

In this webinar we will detail the latest technological advancements for accurate simulation of three-dimensional metallic crack growth via coupled finite element analysis (FEA) and fatigue life computations. Additionally, we will examine why the development of more complex crack growth models requires both tighter control over numerical errors (i.e. solution verification) and rigorous benchmarking to standard handbook solutions and available experimental data (i.e. model validation).

StressCheck is a comprehensive Windows 10-compatible, 64-bit finite element analysis software (FEA) tool with a fully integrated pre- and post-processor and a suite of solver and analysis modules that support advanced engineering computations in applications of solid mechanics. Productivity tools are available to import NASTRAN bulk data file meshes and CAD geometry, perform 2D and 3D automatic meshing, automate analyses via StressCheck‘s API, and more. StressCheck is ideally suited for damage tolerance and forensic engineers who need the best representation of 2D or 3D SIF’s, ERR’s and beta factors for input in sophisticated crack growth simulations, or when analyzing repairs for mitigation of cracks.

AFGROW is a Damage Tolerance Analysis (DTA) framework that allows users to analyze crack initiation, fatigue crack growth, and fracture to predict the life of metallic structures. AFGROW (Air Force Grow), was originally developed by The Air Force Research Laboratory. It is now being developed and maintained by LexTech, Inc. AFGROW is one of the most efficient and widely used crack growth life prediction tools available today. AFGROW is mainly used for aerospace applications; however, it can be applied to any type of metallic structure that experiences fatigue cracking. AFGROW is also a very flexible and user-friendly computer program.

BAMF is used for fatigue analysis, and it is capable of predicting the growth of fatigue cracks in 3D parts. Starting from an assumed initial flaw, BAMF combines stress and crack growth analyses to predict the evolution of crack shape and size in 3D. BAMF provides a robust and automated link between two leading tools: AFGROW and StressCheck. Key features of BAMF include: natural crack shape evolution, fully 3D fatigue analysis capability, complex loading support, multiple cracks, and residual stress compatibility.

ESRD will be exhibiting at AA&S 2018 in Jacksonville, FL from April 23-26! Come visit us at our booth (112) to chat about S.A.F.E.R. Numerical Simulation in the hyper-competitive A&D industry […]

July 17, 2019 @ 1:00 pm EST 3D Crack Growth Simulation: Advancements & Applications Strategies for seamlessly integrating the advanced...

This past week at AA&S/PS&S 2019, ESRD’s Gordon Lehman provided a training course titled “How Do You Verify the Accuracy of Engineering Simulations?”, chatted with attendees about StressCheck and how it supports detailed aerostructures analyses, and exhibited at our colorful & engaging booth.

Read the summary of events and download the AA&S/PS&S training course presentation!

When performing parametric structural analysis, ESRD’s p-element StressCheck FEA software is always my preferred choice due to the excellent solution quality, parametric framework, and superior computational efficiency. In fact, I recently used StressCheck to generate stress intensity factors along a parametrically defined elliptical crack-tip across 3,000 unique geometric configurations. Considering multi-body contact was present and all simulations were performed using a laptop, this was a task well suited for StressCheck.

© 2025 · Engineering Software Research & Development, Inc. | Terms & Conditions | Privacy & Cookie Policy | Software License Agreement | Software Maintenance and Technical Support Policy