What inhibits the use of FEA for DaDT applications in the A&D Industry?

In this “S.A.F.E.R. Simulation” post we will share the key takeaways for engineers and their managers from a recent ESRD...

In this “S.A.F.E.R. Simulation” post we will share the key takeaways for engineers and their managers from a recent ESRD...

Want to learn from the experts in FEA-based Simulation Application (Sim App) development for standardization & automation of complex engineering analysis tasks, such as 3D fatigue crack growth, 3D ply-by-ply laminated composite analysis or other challenging applications you’d like to safely put into the hands of non-experts?

This July, ESRD will be partnering with several industry leaders to provide not one but TWO stimulating webinars on the latest in FEA-based Sim App development.

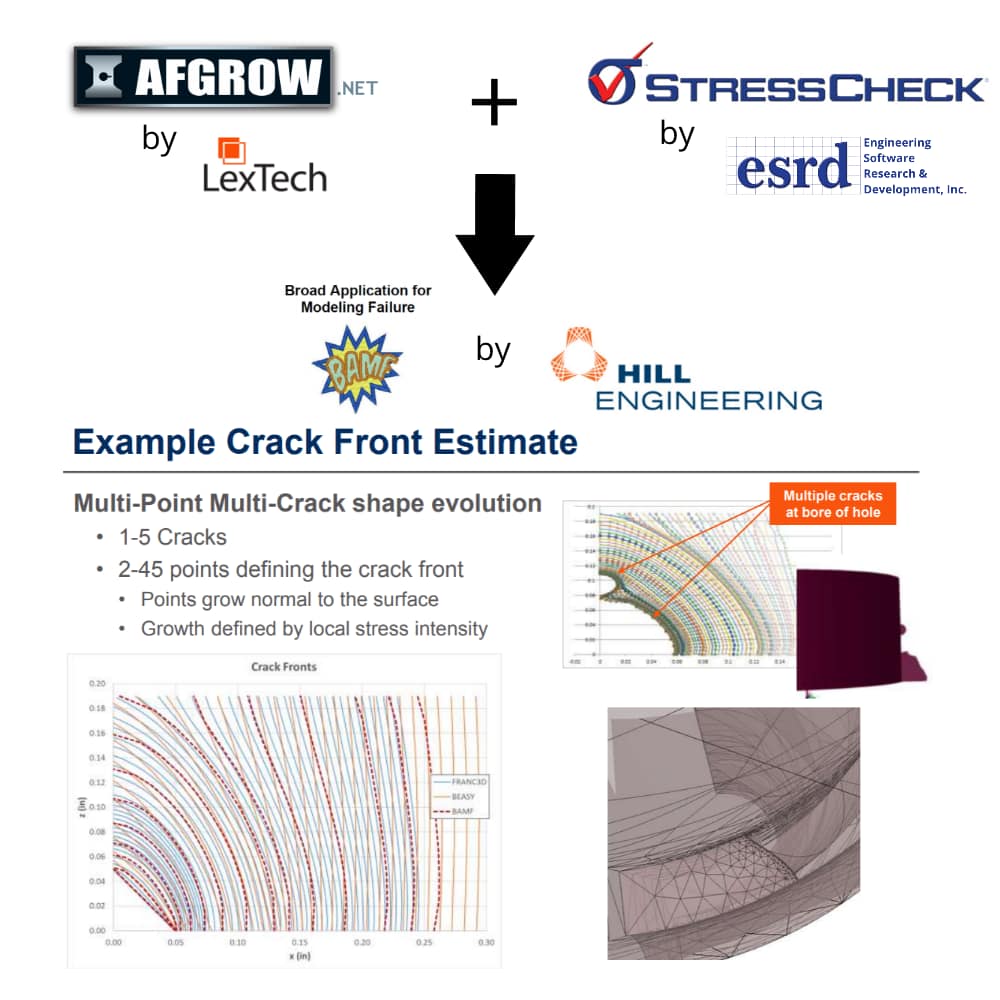

Hill Engineering and ESRD have executed a joint marketing agreement to collaboratively promote the combined use of our software tools Broad Application for Modeling Failure (BAMF) and StressCheck Professional, respectively, for the engineering applications of fatigue and damage tolerance analysis.

On July 17, 2019 a joint webinar on the latest developments in FEA-based 3D crack growth simulation, titled “3D Crack Growth Simulation: Advancements & Applications”, was provided by ESRD’s Brent Lancaster, LexTech’s James Harter and Hill Engineering’s Joshua Hodges. In case you missed it, the webinar recording is now available!

ESRD is pleased to join Hill Engineering, LLC (developers of BAMF) and LexTech, Inc. (developers of AFGROW) for a joint webinar on July 17, 2019 @ 1:00 pm EST.

This collaborative webinar will be titled “3D Crack Growth Simulation: Advancements & Applications”, and will detail the latest technological advancements for accurate simulation of three-dimensional metallic crack growth via coupled finite element analysis (FEA) and fatigue life computations.

July 17, 2019 @ 1:00 pm EST

Strategies for seamlessly integrating the advanced fracture & DaDT capabilities of two numerical simulation software products into a state-of-the-art 3D fatigue crack growth application will be explored.

This webinar is now available to watch on-demand.

In this webinar we will detail the latest technological advancements for accurate simulation of three-dimensional metallic crack growth via coupled finite element analysis (FEA) and fatigue life computations. Additionally, we will examine why the development of more complex crack growth models requires both tighter control over numerical errors (i.e. solution verification) and rigorous benchmarking to standard handbook solutions and available experimental data (i.e. model validation).

StressCheck is a comprehensive Windows 10-compatible, 64-bit finite element analysis software (FEA) tool with a fully integrated pre- and post-processor and a suite of solver and analysis modules that support advanced engineering computations in applications of solid mechanics. Productivity tools are available to import NASTRAN bulk data file meshes and CAD geometry, perform 2D and 3D automatic meshing, automate analyses via StressCheck‘s API, and more. StressCheck is ideally suited for damage tolerance and forensic engineers who need the best representation of 2D or 3D SIF’s, ERR’s and beta factors for input in sophisticated crack growth simulations, or when analyzing repairs for mitigation of cracks.

AFGROW is a Damage Tolerance Analysis (DTA) framework that allows users to analyze crack initiation, fatigue crack growth, and fracture to predict the life of metallic structures. AFGROW (Air Force Grow), was originally developed by The Air Force Research Laboratory. It is now being developed and maintained by LexTech, Inc. AFGROW is one of the most efficient and widely used crack growth life prediction tools available today. AFGROW is mainly used for aerospace applications; however, it can be applied to any type of metallic structure that experiences fatigue cracking. AFGROW is also a very flexible and user-friendly computer program.

BAMF is used for fatigue analysis, and it is capable of predicting the growth of fatigue cracks in 3D parts. Starting from an assumed initial flaw, BAMF combines stress and crack growth analyses to predict the evolution of crack shape and size in 3D. BAMF provides a robust and automated link between two leading tools: AFGROW and StressCheck. Key features of BAMF include: natural crack shape evolution, fully 3D fatigue analysis capability, complex loading support, multiple cracks, and residual stress compatibility.

July 17, 2019 @ 1:00 pm EST 3D Crack Growth Simulation: Advancements & Applications Strategies for seamlessly integrating the advanced...

ESRD’s Dr. Ricardo Actis attended and presented with technology partner Analytical Processes/Engineered Solutions (AP/ES) at the Engineered Residual Stress Implementation (ERSI) Workshop 2019 in Clearfield, UT. The goal of this annual workshop is to develop a roadmap for the implementation of the beneficial effect of engineered residual stresses in damage tolerance analysis (DTA).

Also, ESRD would like to extend our sincerest congratulations to the Washington University St. Louis racing team, who we sponsored this past year to improvements in multiple events, including engineering design. Great job, team!

ESRD’s Dr. Ricardo Actis attended and presented with technology partner Analytical Processes/Engineered Solutions (AP/ES) at the Engineered Residual Stress Implementation (ERSI) Workshop 2018 in Clearfield, UT. This annual workshop is focused on the development of a damage tolerance methodologies for fatigue crack growth through deep Engineered Residual Stress (ERS) fields.

“We have been having very good success using the P-Version finite element code, StressCheck, to develop the 2-D solutions for two independent cracks in a plate. I have asked one of our AFGROW team members to model the plate and lug cases using StressCheck and compare them to the existing AFGROW closed-form solutions. [He] modeled the cases several different ways to be sure that he was getting the best possible solutions. He has verified that the bearing load option in StressCheck provides excellent results.”

© 2026 · Engineering Software Research & Development, Inc. | Terms & Conditions | Privacy & Cookie Policy | Software License Agreement | Software Maintenance and Technical Support Policy