ESRD has been helping aerospace and defense (A&D) engineering professionals solve the toughest problems in strength, durability and damage tolerance of metallic and composite structures since 1989.

Applications & Simulations

We developed the world’s premier high-order FEA tool, StressCheck Professional, to empower our customers to obtain reliable solutions to their challenging engineering applications.

Schedule an Application Demo

Would you like a no-cost demonstration of our engineering application solutions? Complete our Request an Engineering Application Demo form and we will get back to you shortly.

What Are Your Engineering Analysis Goals?

Are high-resolution stress or strain gradients important to you? Or, any of the following?:

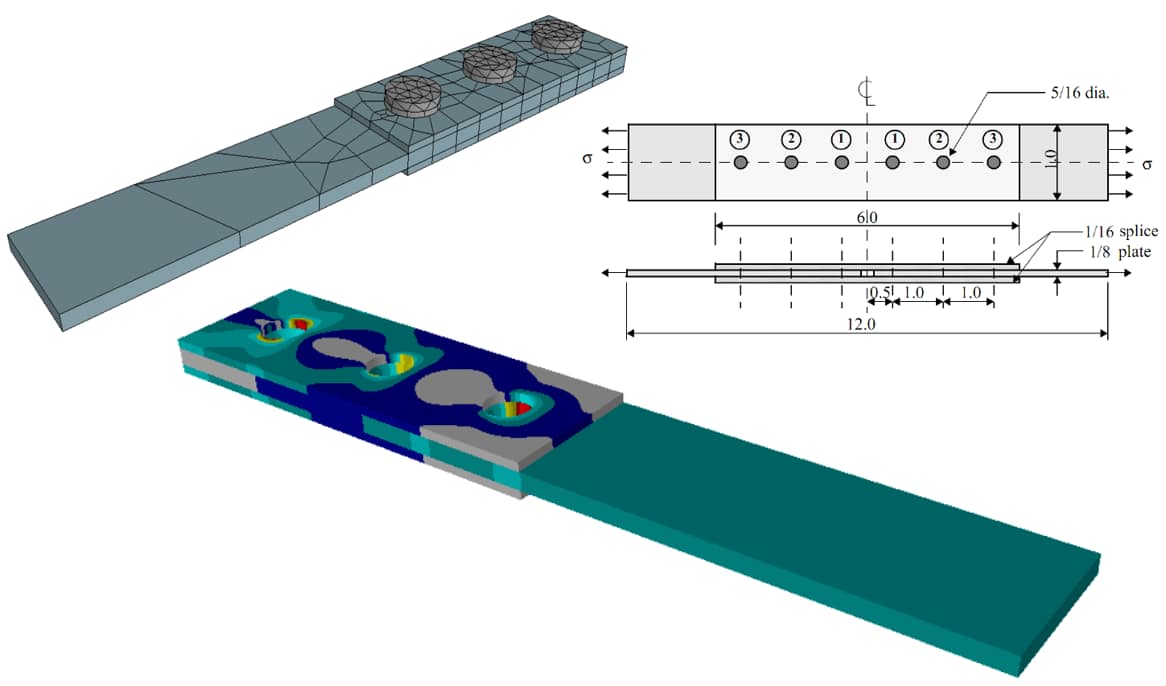

- Stress concentrations for small and/or difficult to analyze features

- Adhesively bonded ply by ply laminated composites details

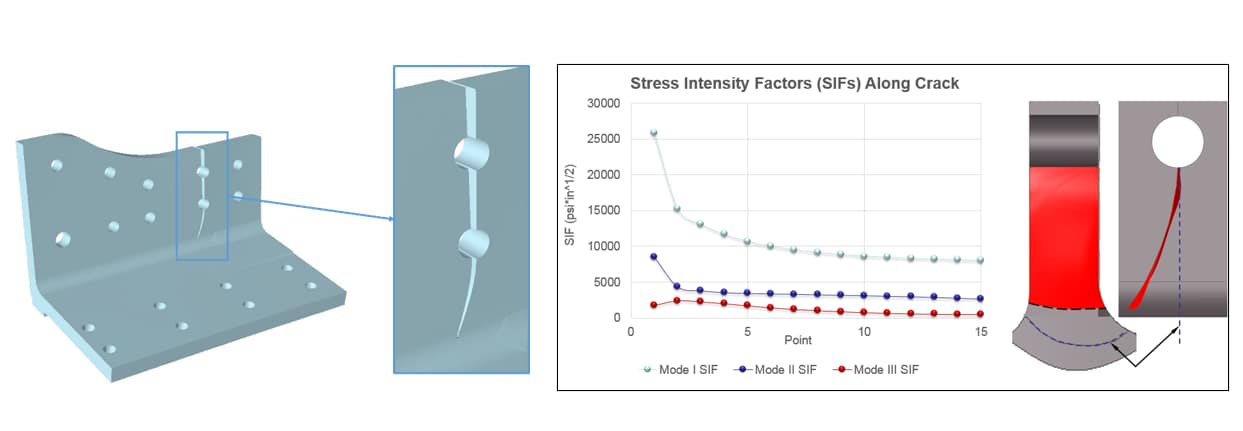

- 3D stress intensity factors (SIF) for user-defined crack geometries

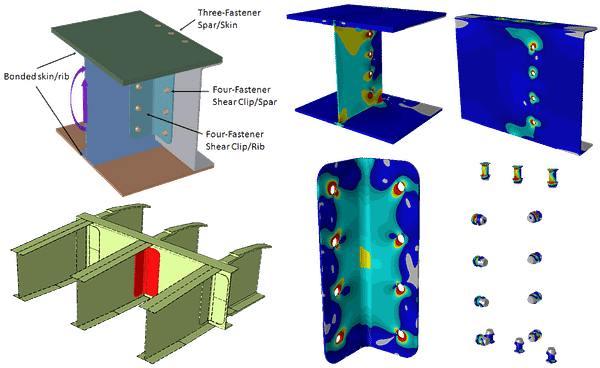

- Multi-body contact analyses of fastened joints

- Residual stress due to cold-working process

- Global-local analysis of airframe details

- Customized engineering simulation apps

If so, then there is a high probability that we can help you achieve your present (and future) simulation goals with our software products.

Application & Simulation Focus

The following section highlights key engineering applications, and related solid mechanics problem classes, that are well-suited for ESRD’s numerical simulation technology:

Would you like to schedule an Application Demo?

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“We have found StressCheck very useful for computational fracture mechanics for both metallic and composite components. In recent years it has been extensively used in determining beta factors for RAAF’s C-130 Wing DTA locations and associated generic research.”

Dr. Manfred Heller

Head - Structural Mechanics, DSTO

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989